Operational clarity inside global supply chains

Part 2 of the fast, friendly & dedicated editorial series. In this piece, we step inside a less visible cost of modern logistics: the difference between execution and continuity when logistics does not walk alongside the operation, from origin to destination.

Global manufacturing supply chains do not operate in chaos. They operate under constant pressure and uncertainty. And yet, they must remain continuous.

Components sourced from multiple countries move simultaneously toward production lines that cannot afford to stop. According to the International Energy Agency, building a single electric vehicle model today can involve suppliers across as many as 50 countries, a level of geographic dispersion that turns logistics into a permanent coordination challenge rather than a linear flow.

Materials cross borders under different regulatory regimes, transit windows, and capacity constraints, while production schedules continue to adjust in real time. Even as global trade takes sharp turns, operations keep moving.

In this environment, logistics is not a support function. It is a direct extension of production continuity.

The quiet cost behind continuity

Even when operations keep moving, the conditions under which decisions are made are rarely stable or fully visible.

Despite the increasing digitalization of supply chains, 37% of manufacturers still struggle with shipment visibility, leaving critical decisions exposed to partial or delayed information across global operations. Information exists, but it is fragmented across systems, partners, and regions.

What appears viable at origin can quietly introduce friction at destination. What protects one segment of the chain can shift risk downstream.

Disruptions in manufacturing supply chains rarely arrive as sudden events. Nearly 80% of organizations faced some form of supply disruption last year, according to World Economic Forum insights—not as isolated shocks, but as overlapping pressures accumulating across their networks.

A component lands later than expected.

A routing decision protects today’s schedule but creates tomorrow’s bottleneck.

Capacity tightens after plans are locked in.

Each situation is manageable by any standard logistics partner. Most perform reliably within scope: they execute instructions, respond to questions, and deliver against defined parameters. In stable conditions, that approach works.

The cost emerges when these signals are read late, without operational context across volatile, multi-country supply chains where decisions must adapt in motion.

What is often missing is orientation.

A shared operational reading of what matters now, where risk is forming, which options preserve flexibility, and which ones quietly close recovery paths.

Without that layer, context must be rebuilt repeatedly. Risks surface after execution begins. Escalations replace anticipation.

Over time, the cost is not only operational or financial. It is cognitive.

Decisions simply carry more weight than they should.

When friendly starts to matter

At this point, the distinction becomes clear. Execution keeps supply chains moving and continuity depends on whether someone is walking alongside the operation while decisions are still being made.

This is where Friendly begins to matter.

A concept often misunderstood in logistics. It is not a tone. It is neither politeness nor making complexity easier to accept.

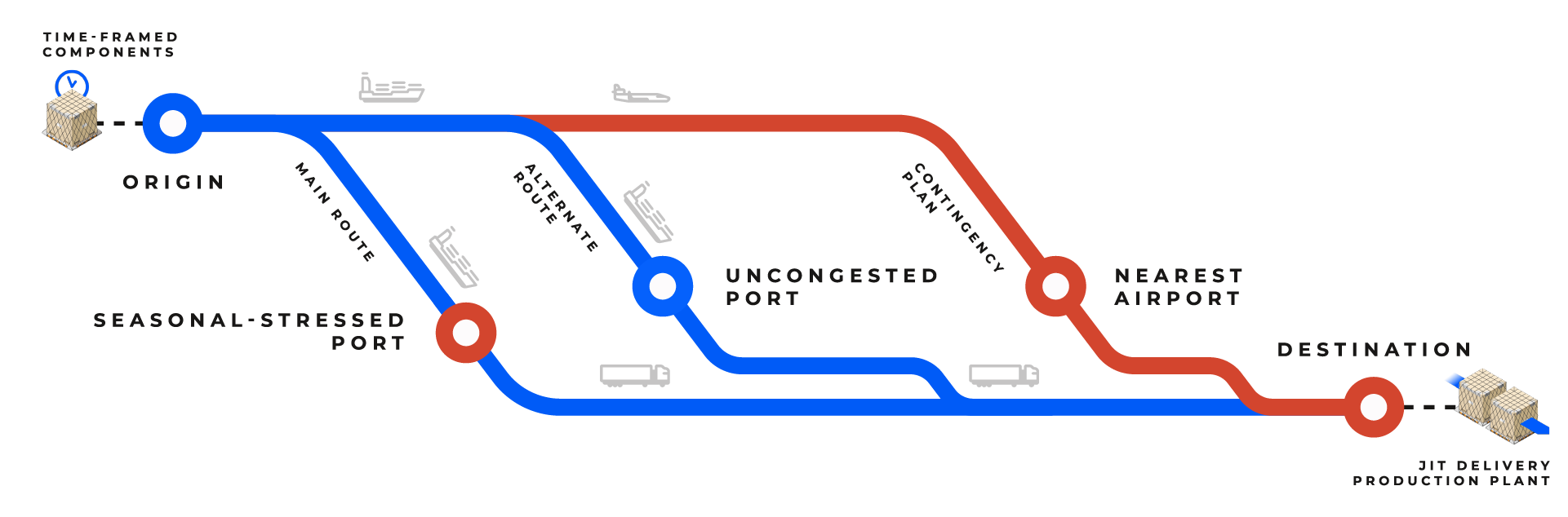

Friendly describes an operating relationship in which logistics does not sit outside the business, waiting for instructions, but moves with it—sharing context, surfacing implications early, and helping shape decisions before execution locks options in.

This relationship is built by experts on both the origin and destination sides who understand local constraints, regulatory dynamics, carrier behavior, and industrial operating conditions.

By being present where logistics becomes real—ports, airports, and industrial hubs where capacity, compliance, and cut-off times create non‑negotiable limits.

By operating a network of own offices that does more than provide coverage, enabling rapid escalation, direct carrier orchestration, and real‑time operational judgment.

And by technology that connects data, risk signals, execution status, and expert insight into one shared reading environment. Not just visibility, but a decision cockpit designed for early action.

Friendly is not a soft attribute. It is a decision-support operating model within complex manufacturing supply chains, acting as an extension of the operation while decisions are still being formed.

The xpd global standard of FRIENDLY

Up to this point, friendly has been described as a way of working alongside the operation rather than outside of it. That kind of presence does not happen by intention alone. It requires an operating model deliberately built to sustain involvement while decisions are still open.

This is how we operate at xpd global.

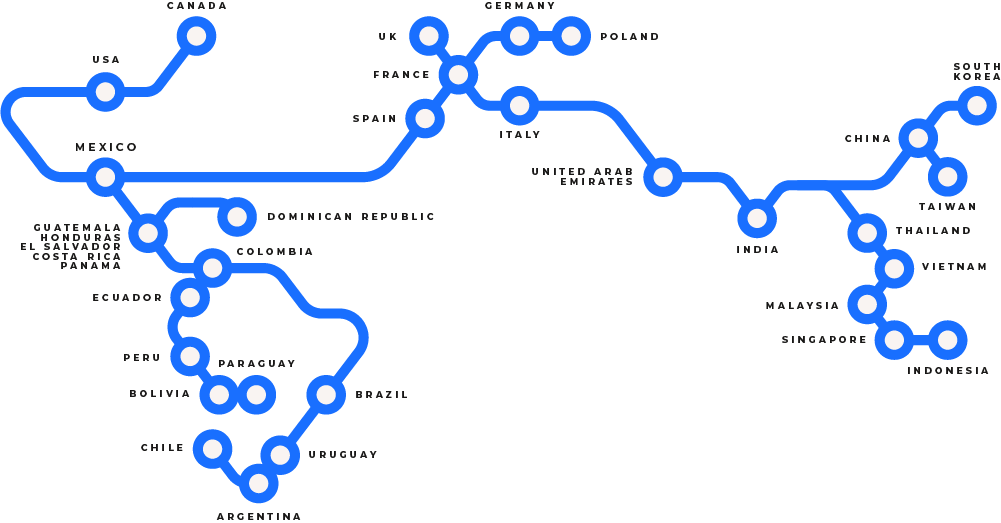

Having teams in both origin and destination, with more than 100 own offices near main ports and airports, is not primarily about proximity or coverage. It is about connecting realities that rarely surface together in one place. What is feasible at origin, what typically creates friction at destination, how markets react to small shifts, and where flexibility truly exists are read together—before a plan is locked in.

This changes the nature of guidance.

Not simply moving information faster but engaging earlier. Not reacting to issues once they escalate but surfacing implications while there is still room to adjust.

This way of operating is reinforced by culture—as an operating expectation, not a value statement. Being prompt is not limited to responding quickly, but to entering the decision early. Accountability means staying connected to outcomes, not just completing tasks. Passion to serve is expressed through involvement, not merely execution.

Because these behaviors are embedded, friendly does not depend on who is involved. It depends on how the organization operates.

This is how friendly becomes consistent—not as a promise, but as an operating standard that supports continuity in complex manufacturing supply chains, before anything moves.

Learn how our people, culture, and operating model support continuity across global supply chains.

Sources referenced for the data points and research ideas mentioned

The International Energy Agency (IEA) — Global EV Outlook 2023:

https://www.iea.org/reports/global-ev-outlook-2023

Globe Newswire — New Research from Tive Reveals that 37% of Companies Can’t Track In-Transit Cargo: https://www.globenewswire.com/news-release/2025/03/04/3036558/0/en/New-Research-from-Tive-Reveals-that-37-of-Companies-Can-t-Track-In-Transit-Cargo.html

World Economic Forum — From supply-chain upheaval to AI-led transformation, here’s how industry leaders are keeping up: https://www.weforum.org/stories/2025/05/industry-leaders-priorities-geopolitics-technology/?utm_source=chatgpt.com